Gelatin powder is widely used in food, pharma, and cosmetic industries. Its sensitive nature requires special care during processing and formulation stages. Traditional high-shear blending can damage gelatin’s delicate molecular structure easily. This leads to loss of functionality, reduced gel strength, and instability. Hence, manufacturers are shifting toward low shear blending for better results.

Low shear blending ensures uniform mixing without degrading the gelatin particles. It helps maintain key properties like bloom strength and dispersibility throughout. Unlike high-speed mixers, this method avoids heat and mechanical stress. The process also minimizes dusting, static buildup, and particle segregation effectively. This makes it ideal for high-quality, reproducible gelatin-based formulations globally.

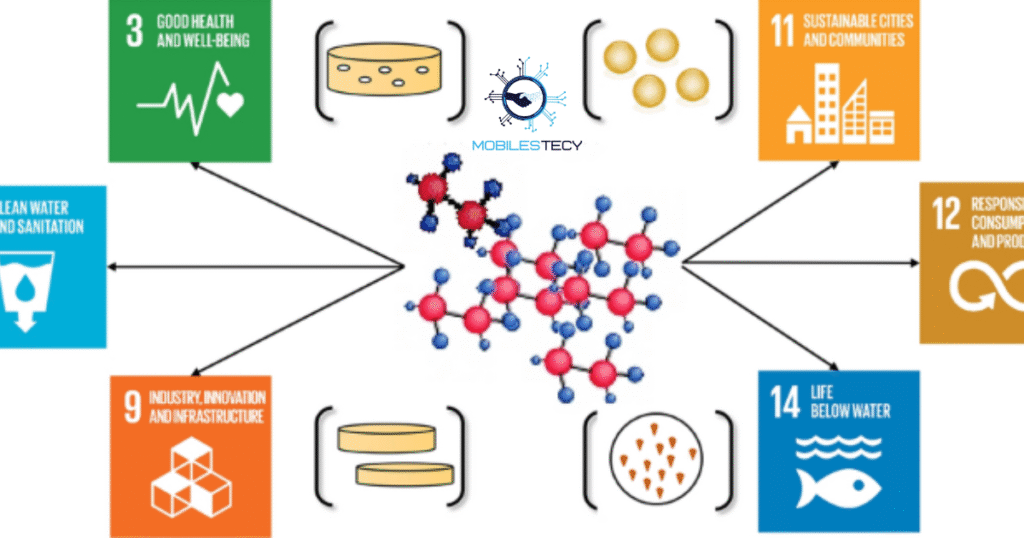

As demand rises for stable and clean-label gelatin products, technology evolves. Low shear systems now include smart controls, closed loops, and automation. Industries benefit from improved consistency, efficiency, and regulatory compliance standards. This article explores low shear gelatin blending, its benefits, and innovations. Understanding this process is crucial for modern, quality-driven production environments.

Understanding the Importance of Low Shear in Gelatin Blending

Gelatin powder is highly sensitive to temperature, friction, and mechanical stress. Improper handling can degrade its structure, affecting performance in applications. Maintaining bloom strength and viscosity is crucial during the blending process. High shear mixers often create excessive heat, leading to product instability. Low shear technology prevents this, preserving pectin’s natural functional properties.

Industries like pharmaceuticals and food rely on gelatin’s consistent performance. Any variation in quality can cause defects in capsules, gummies, or desserts. Therefore, uniformity and structural integrity are essential during powder blending. Low shear blending ensures each batch meets strict regulatory and quality standards. This approach enhances safety, compliance, and product reproducibility at scale.

Additionally, pectin is hygroscopic and tends to form lumps when stressed. Fast mixing or high friction can create clumps that dissolve poorly later. Low shear systems gently combine powders without forming hard agglomerates. The result is a homogenous, free-flowing blend that’s easy to process. This improves downstream operations like encapsulation, molding, or tableting significantly.

Benefits of Low Shear Blending for Pectin Powders

Low shear blending prevents thermal degradation of sensitive gelatin molecules. It maintains bloom strength and gelling properties essential for functional integrity. The process avoids overheating, mechanical stress, and unwanted chemical transformations. This leads to more stable, consistent products across all production batches.

Uniform distribution of active ingredients is crucial in pharma-grade pectin blends. Low shear mixing ensures each dose contains the correct ingredient ratio. There’s less segregation, dust formation, or product loss during processing. This makes it ideal for precision applications in regulated industries worldwide.

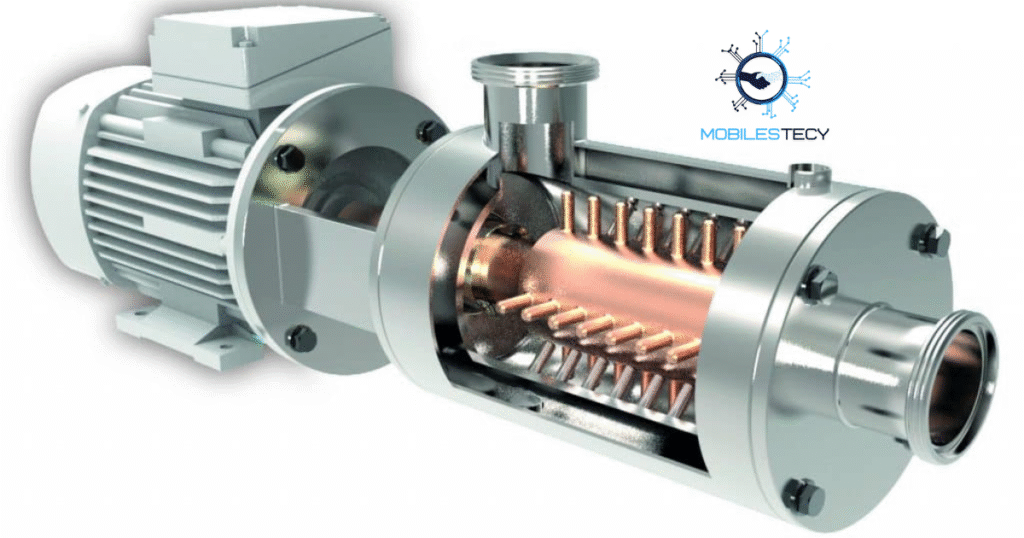

Key Technologies and Equipment Used in Low Shear Blending

Tumble blenders, like V-type and double-cone mixers, are widely used. They rotate gently, allowing powders to mix without particle degradation. This technique is ideal for delicate ingredients like pectin or vitamins. They offer excellent uniformity with minimal shear and energy consumption. Their simple design also allows easy cleaning and low maintenance efforts.

Ribbon blenders can be modified for low shear pectin blending tasks. By reducing blade speed and eliminating choppers, stress is minimized. They work well for combining gelatin with sugars or flavor powders. Controlled motion helps maintain the physical structure of all components. These blenders are scalable for pilot trials and large production lines.

Intermediate bulk container (IBC) blenders offer closed-system powder blending advantages. They eliminate transfer steps, reducing contamination and dust exposure risks. Gelatin blends evenly with other materials within a sealed container. This method supports consistent, GMP-compliant pharmaceutical and nutraceutical manufacturing. Modern IBCs also integrate sensors for blend uniformity validation in real time.

Challenges Faced in Pectin Powder Blending

The sticky and cohesive nature of gelatin often leads to issues like bridging, clumping, and poor powder flow during the blending process. These challenges can disrupt material movement and cause inconsistencies in the final mixture.

External factors such as temperature and humidity significantly influence the blending quality of gelatin-based powders. Excess moisture can trigger premature gelling, agglomeration, or sticking within the mixing chamber. To maintain uniformity and stability, operations often require humidity-controlled environments and moisture-resistant system designs.

Industries Benefiting from Low Shear Pectin Blending

Pharmaceutical companies use low shear blending for softgel and capsule formulations. Maintaining gelatin structure is vital for drug stability and bioavailability. Accurate blending of APIs with pectin ensures uniform therapeutic effects. It also reduces production errors and supports regulatory compliance globally.

Food and nutraceutical industries depend on pectin for texture and stability. Low shear blending supports cleaner labels and better ingredient transparency. It prevents burning or loss of gelatin during high-speed processing. This ensures quality in gummies, desserts, powders, and protein formulations.

Advantages and Future of Low Shear Pectin Blending Technology

Low shear blending preserves gelatin’s properties while ensuring product safety. It reduces static buildup, dust emissions, and material loss during processing. Operators benefit from cleaner workspaces and lower health-related handling risks. These systems also offer improved batch-to-batch consistency in final products. This makes them essential in regulated industries like pharma and food.

Energy efficiency is another strong advantage of low shear mixing systems. They consume less power and reduce the need for heat dissipation. This lowers operational costs while supporting eco-friendly manufacturing practices. Companies adopting these technologies often see improved sustainability metrics. It aligns well with modern green initiatives and environmental compliance goals.

Looking ahead, innovation will bring automation and real-time monitoring enhancements. Smart sensors will detect blend uniformity, moisture, and particle behavior. AI-driven controls could adapt blender speed and time dynamically. These developments aim to maximize quality while reducing operator intervention. Low shear blending will remain critical in next-generation pectin applications.

Future Trends in Pectin Blending Technology

Automation is becoming a major focus in modern blending systems design. Real-time sensors monitor temperature, humidity, and particle movement continuously. Adjustments to mixing speed and time are made automatically for accuracy. These advancements enhance efficiency, product safety, and process traceability.

Sustainable manufacturing is driving interest in energy-efficient blending solutions. Low shear systems use less power and generate minimal heat or waste. Designs now support clean-in-place (CIP) and reduced water usage technologies. Such features meet the growing demand for eco-friendly production methods.

- Low shear blending protects gelatin’s structure during sensitive mixing operations.

- This technology ensures uniform mixing of pectin with active ingredients.

- Equipment like tumble blenders and IBCs provide gentle, controlled mixing.

- Gelatin’s hygroscopic nature requires strict control of humidity and temperature.

- Future innovations include smart sensors and automated speed adjustments.

Faq’s

What is low shear blending and why is it important for gelatin?

Low shear blending mixes gelatin without damaging its functional structure. It preserves bloom strength, avoids clumping, and improves final product quality.

How does low shear blending differ from high shear mixing processes?

Low shear uses slower speeds with minimal heat or mechanical force. High shear generates heat, friction, and may degrade pectin performance quickly.

What types of equipment are used for low shear pectin blending?

Tumble blenders, ribbon mixers, and IBC blenders are commonly used. These systems ensure gentle, uniform mixing with reduced stress on particles.

Can low shear blending be used in pharmaceutical-grade applications?

Yes, it ensures uniform API distribution and complies with GMP standards. It’s ideal for capsules, softgels, tablets, and powdered supplements production.

What are the environmental advantages of low shear blending systems today?

They consume less energy and generate minimal heat and airborne dust. Modern systems support sustainable production with better operational efficiency overall.

Conclusion

Low shear blending offers a reliable solution for processing sensitive gelatin powders. It maintains functional properties like gel strength and consistent particle distribution. Industries benefit from improved safety, efficiency, and final product performance. The technology reduces heat damage, clumping, and material degradation during blending. This approach supports high-quality standards across food, pharma, and cosmetic sectors.

Advanced equipment designs now include automation, sensors, and real-time process controls. These innovations help maintain blending precision while reducing manual intervention needs. As demand for cleaner, more consistent products grows, technology continues evolving. Sustainability and compliance are driving future development in powder blending systems. Low shear blending supports these goals with efficient and eco-conscious operation.

Understanding and adopting low shear techniques is essential in modern manufacturing. It enables better control, consistency, and scalability in pectin-based production. Manufacturers should invest in training, validation, and system optimization regularly. The future lies in smart, safe, and sustainable blending technologies worldwide. Low shear pectin blending is a cornerstone of quality-focused processing systems.

Read more latest Articles on Mobilestecy.com