Industrial baling wrapping technology is essential in modern manufacturing and logistics. It compresses materials into dense bales for easier handling and storage. Wrapping protects these bales from damage during transport and harsh environmental conditions. This technology improves efficiency in waste management and recycling operations significantly. It also helps reduce costs and optimize space in warehouses.

The demand for sustainable packaging solutions has driven advances in baling wrapping systems. Automated balers and wrappers now increase productivity with minimal human intervention. These machines use hydraulic pressure to compact materials tightly into uniform shapes. Wrapping films secure bales, preventing contamination from moisture, dust, and dirt. This technology supports industries like agriculture, manufacturing, and recycling worldwide.

Industrial baling and wrapping machines come in various types, serving different needs. Vertical balers suit small spaces, while horizontal balers handle high-volume material processing. Two-ram balers efficiently compress bulky scrap materials into dense, manageable bales. Wrapping techniques include stretch film, netting, and heat shrink for different applications. Together, baling and wrapping technologies streamline material handling, storage, and transport.

Types of Industrial Balers

Vertical balers are ideal for small operations with limited space available. They compress materials vertically, using hydraulic pressure for dense bale formation. Their compact design makes them easy to install in retail settings. These machines reduce labor and improve recycling efforts significantly. Vertical balers are cost-effective and simple to operate daily.

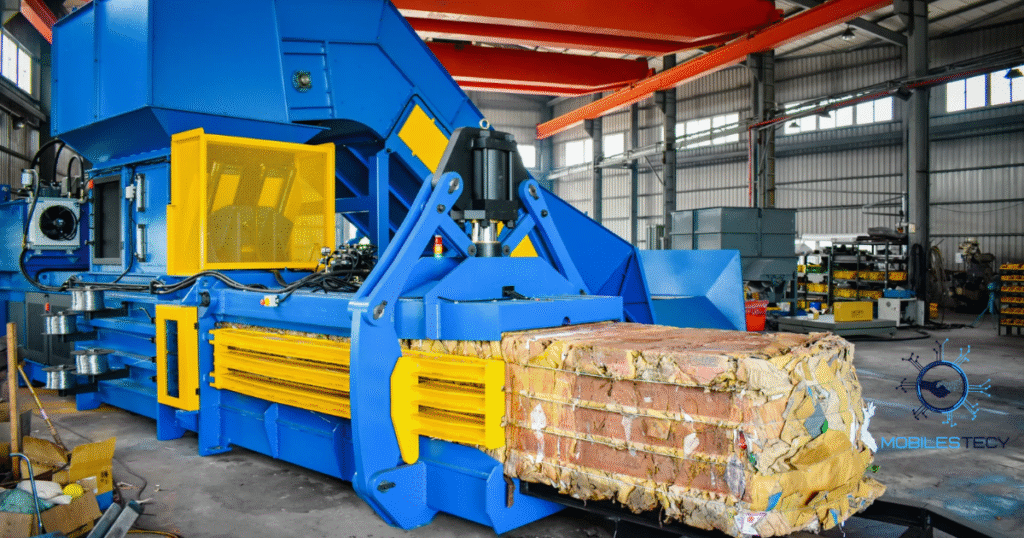

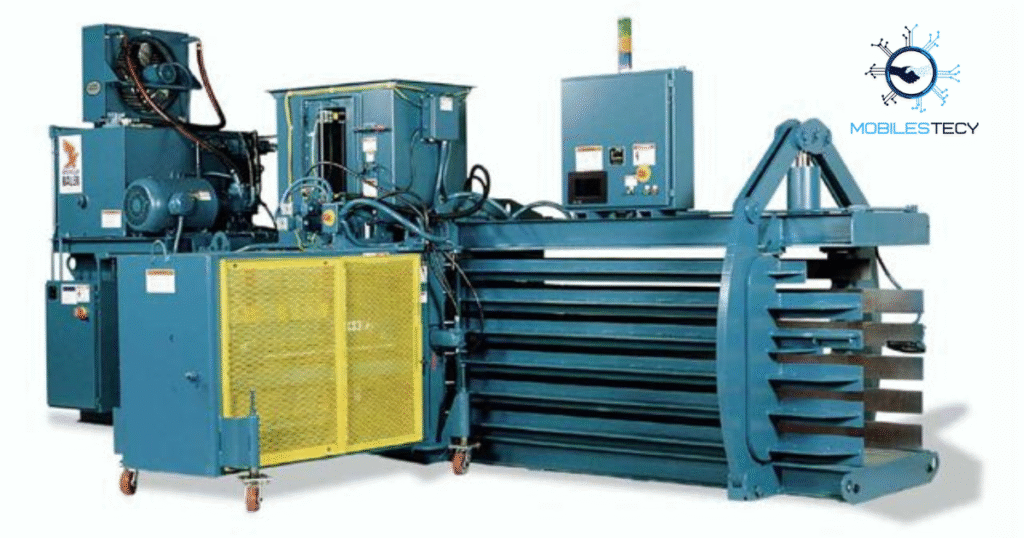

Horizontal balers serve high-volume industries requiring large, dense bales for transport. These balers compress materials horizontally, often with automatic feeding systems included. Their larger size enables processing bulky materials like cardboard and plastics. Horizontal balers increase throughput while minimizing material handling time. They improve operational efficiency in large manufacturing plants.

Two-ram balers combine two hydraulic rams for compression and bale ejection. These machines handle heavy, bulky materials such as scrap metals efficiently. Two-ram balers produce uniform, high-density bales for easier storage and shipping. Their advanced design supports industrial recycling and waste management processes. They offer flexibility in processing a wide range of materials.

- Industrial baling technology compresses recyclable materials into dense, manageable bales efficiently.

- Wrapping secures bales, protecting them from moisture, dirt, and damage during transport.

- Vertical balers suit small operations with limited space and moderate material volume.

Wrapping Technologies in Industrial Baling

Stretch film wrapping uses highly flexible plastic films to secure bales evenly and firmly. This method shields materials from moisture, dust, and external contaminants, ensuring the integrity of the packed contents. Its affordability and reliability make it a preferred choice in multiple sectors. Automated wrapping systems further enhance efficiency by delivering precise and uniform film coverage. This technology is extensively adopted in agricultural, manufacturing, and recycling industries for its strong protective performance.

Net wrapping employs a plastic mesh that allows air circulation while keeping materials tightly contained. It’s particularly effective for hay, straw, and silage bales, reducing spoilage during long-term storage. The open design of the net enables ventilation, preventing mold buildup and moisture retention. This method offers the perfect combination of containment, breathability, and durability, especially for perishable agricultural goods.

Shrink wrapping uses heat to mold plastic film snugly around bales, creating a sealed and weatherproof layer. It provides excellent defense against rain, dirt, and transportation damage, making it ideal for long-haul shipments or outdoor storage. Compared to other wrapping styles, shrink wrapping offers exceptional sealing strength and aesthetic finish. While it’s more common in specialized or high-value industries, it ensures the highest level of protection and product preservation for sensitive materials.

Advantages of Automated Baling Systems

Automated baling systems increase production speed by reducing manual intervention time. They allow continuous operation, which boosts overall facility throughput effectively. Precise control over compression improves bale density and uniformity consistently. Automation also enhances worker safety by minimizing physical labor and injuries.

These systems integrate sensors to monitor pressure and material flow in real-time. Operators receive alerts for maintenance, preventing unexpected breakdowns and downtime. Automation reduces film waste by controlling wrapping tension and overlap perfectly. The improved efficiency lowers operational costs and increases profitability significantly.

Benefits of Industrial Baling and Wrapping

Industrial baling reduces material volume dramatically, optimizing warehouse and transport space. Smaller bale sizes mean fewer shipments and reduced fuel consumption during transit. This reduction results in lower costs and improved environmental sustainability overall. Compact bales also facilitate easier handling with forklifts and cranes safely. Baling helps companies meet efficiency goals in material processing and logistics.

Industrial baling & Wrapping technology protects bales from contamination, preserving material quality during storage. It keeps moisture, dirt, and pests away from valuable recyclable or agricultural goods. Wrapped bales maintain integrity throughout transport, reducing damage and waste significantly. This protection supports higher resale value and compliance with industry standards. Wrapping contributes to safer, cleaner workplaces and supply chains.

Together, baling and wrapping improve operational efficiency by automating packaging processes. Automation reduces labor requirements, increases throughput, and ensures consistent bale quality. Smart controls enable precise pressure and wrapping tension adjustments automatically. These technologies integrate with other material handling equipment in facilities. Overall, they streamline workflows and cut operational costs.

- Horizontal balers handle high-volume materials, improving throughput in large-scale industries.

- Stretch film wrapping provides tight, elastic coverage that holds bales firmly together.

- Net wrapping allows airflow while protecting agricultural bales like hay or straw effectively.

Innovations Shaping the Future of Baling Wrapping

Automation advancements include robotic arms that wrap bales quickly and with precision. These robots reduce film waste by applying exact amounts during the wrapping cycle. Sensors monitor bale dimensions, allowing machines to adjust wrapping patterns in real time. Automation also helps reduce manual labor and associated safety risks significantly. This trend is transforming how facilities handle material packaging efficiently.

Eco-friendly wrapping films made from biodegradable materials are gaining popularity in industries. These films reduce plastic waste and help companies meet sustainability targets easily. Researchers are developing plant-based films that break down faster in composting environments. Using recyclable and compostable films supports circular economy principles effectively. This innovation aligns packaging with growing environmental regulations globally.

IoT technology integration allows real-time machine monitoring and predictive maintenance capabilities. Data analytics help optimize baler and wrapper performance, reducing downtime and failures. Remote control and diagnostics improve machine uptime and production reliability dramatically. IoT-enabled machines also provide detailed reporting for supply chain transparency. Smart connectivity is a game-changer for industrial packaging operations.

Sustainable Materials in Industrial Baling & Wrapping Technology

Eco-friendly wrapping films are designed to break down naturally after disposal. These biodegradable films reduce environmental pollution caused by traditional plastic wrap. They are often made from plant-based materials like cornstarch or sugarcane derivatives. Many companies are adopting these sustainable options to meet green initiatives.

Recyclable stretch films allow easy recovery and reuse of plastic materials afterward. Innovations focus on reducing the thickness while maintaining strength and elasticity. This leads to less raw material use and reduced carbon footprint. Sustainable wrapping materials align with circular economy goals and regulatory compliance.

- Automated baling systems reduce labor costs and improve consistency across production lines.

- Eco-friendly biodegradable films minimize plastic waste and promote environmental sustainability efforts.

- IoT integration enables real-time machine monitoring, predictive maintenance, and performance optimization.

- High-pressure hydraulic balers create ultra-dense bales, reducing storage and transport costs.

- Baling and wrapping technology together enhance workplace safety by preventing material spillage.

Faq’s

What materials can be processed using industrial baling machines?

Industrial balers can handle paper, plastics, metals, textiles, and agricultural products.

How does wrapping protect bales during transportation and storage?

Wrapping prevents moisture, dust, and debris from damaging the compressed materials.

What are the main types of industrial balers available today?

Vertical, horizontal, and two-ram balers are commonly used in various industries.

Are there eco-friendly options for bale wrapping films?

Yes, biodegradable and recyclable films are increasingly used for sustainable packaging.

How does automation improve baling and wrapping efficiency?

Automation increases speed, consistency, and reduces labor costs and human error.

Conclusion

Industrial baling and wrapping technology greatly improves material handling efficiency. It reduces waste volume, lowers transportation costs, and saves valuable storage space. These technologies also enhance workplace safety by securing materials during transport. Automation and smart controls continue to advance the industry rapidly. Overall, they support sustainability and operational excellence across multiple sectors.

The integration of eco-friendly wrapping films aligns with global environmental goals. Biodegradable and recyclable materials help reduce plastic pollution significantly. Innovations in IoT and robotics optimize machine performance and reliability. These advancements allow companies to meet regulatory standards more easily. Sustainable baling solutions play a vital role in circular economies.

Looking ahead, industrial baling and wrapping technologies will become more intelligent. Enhanced automation will drive faster processing and lower labor dependency. New materials will offer improved protection while minimizing environmental impact. Continuous innovation ensures better resource utilization and cost savings. This technology remains essential for efficient, sustainable industrial operations worldwide.

Read more latest Articles on Mobilestecy.com