The electronics industry requires reliable equipment for efficient circuit board assembly processes. Reflow soldering ovens play a central role in ensuring strong solder joints. Honghui Technology has introduced ovens designed to meet modern manufacturing needs. These machines combine precise heating systems with advanced control for consistent performance. Manufacturers worldwide rely on such ovens for quality and dependable production.

Honghui Technology reflow soldering ovens are engineered to support lead-free soldering. They feature multi-zone heating chambers that maintain accurate thermal profiles throughout. This ensures even temperature distribution, preventing soldering defects across sensitive components. The ovens are also energy-efficient, reducing operational costs for manufacturers. Their design meets global standards while keeping safety and efficiency in focus.

In competitive markets, manufacturers seek solutions balancing quality and affordability together. Honghui Technology positions its reflow soldering ovens as cost-effective alternatives. These ovens cater to both small-scale production and large-scale assembly. Their versatility makes them suitable for consumer electronics, LED, and automotive sectors. Strong after-sales support further strengthens their adoption across global manufacturing networks.

Table of Contents

Understanding Reflow Soldering Technology

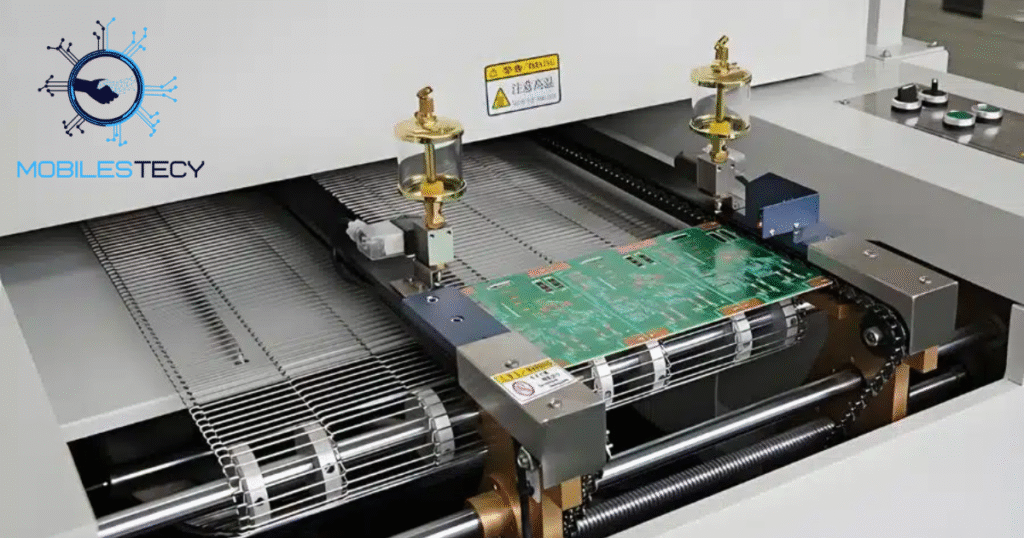

Reflow soldering is a widely used process in surface mount manufacturing. It involves heating printed circuit boards to melt solder and create joints. The process ensures reliable electrical connections across all mounted components. Precision and controlled temperature profiles are essential for avoiding production defects. Modern ovens automate these processes, ensuring repeatability and consistent product quality.

The reflow soldering process is typically carried out in a series of controlled heating phases. These stages include preheating, soaking, reflow, and cooling, each designed to stabilize temperatures and ensure proper solder formation. Careful management of heat ramp-up rates and peak temperature thresholds is essential. Without precise control, circuit boards can experience issues such as solder bridging, void formation, or component malfunction. Therefore, temperature profiling remains a critical factor in maintaining assembly quality.

Advancements in modern manufacturing have significantly improved the performance of reflow soldering equipment. Energy-efficient ovens with digital controls and programmable profiles allow customization for different production lines. Enhanced airflow and circulation systems ensure even heat distribution, especially when working with larger or more complex printed circuit boards.

Precision Through Multi-Zone Temperature Control

Honghui reflow ovens incorporate multi-zone heating systems to achieve highly accurate thermal profiles. Each zone can be adjusted independently, allowing tailored heating for boards that contain diverse components and varying thermal demands.

By distributing heat evenly and gradually, the ovens reduce thermal stress on sensitive components. Controlled temperature transitions prevent thermal shock, protecting delicate semiconductor packages and ensuring long-term reliability.

Features of Honghui Technology Reflow Soldering Ovens

Honghui ovens are designed with multiple heating zones for accuracy. Each zone independently controls temperatures to maintain precise thermal distribution. This allows boards with varied components to achieve optimal soldering profiles. The result is minimized defects and enhanced overall production line yield. Such multi-zone design distinguishes Honghui ovens within competitive equipment markets.

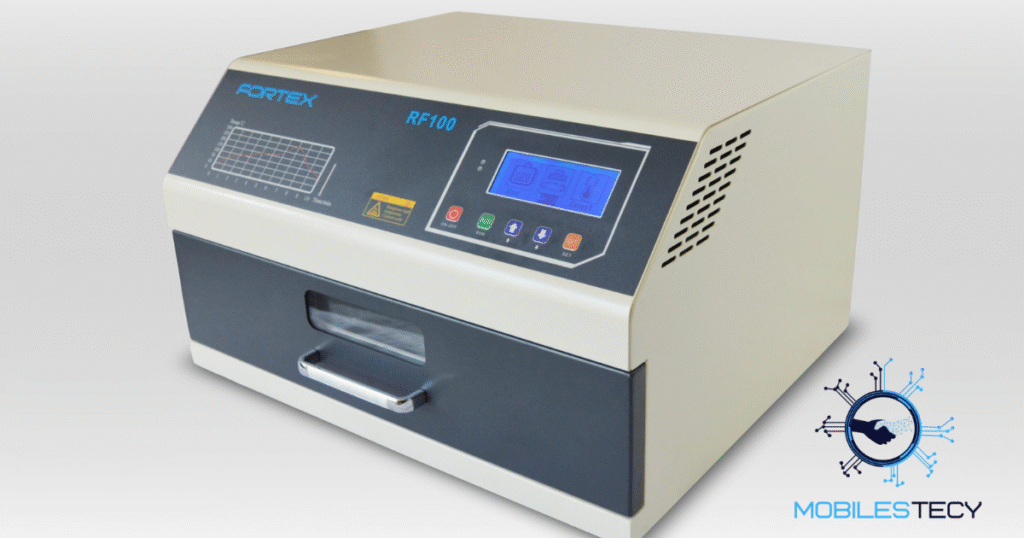

These ovens incorporate advanced PID controllers ensuring accurate heat management. PID regulation minimizes overshoot and stabilizes target temperatures effectively. Users can store and recall multiple profiles for diverse assembly tasks. This versatility supports both prototype runs and high-volume continuous manufacturing. Engineers appreciate their intuitive interface for convenient monitoring and adjustments.

Lead-free soldering compatibility is a standout feature of Honghui ovens. They achieve the required higher peak temperatures with excellent reliability. Strong insulation reduces heat loss, improving energy efficiency and safety. Their compact designs save valuable floor space for growing manufacturers. Collectively, these features enhance productivity while lowering operational manufacturing costs.

Energy Efficiency and Cost Savings

Honghui ovens are built with insulation systems to prevent heat loss. This reduces electricity consumption while maintaining stable internal temperature control. Energy efficiency translates into reduced operating expenses for manufacturing companies. Thus, cost-effectiveness becomes a long-term advantage for competitive production facilities.

The ovens also optimize heating element performance to minimize unnecessary power. This feature ensures sustainability while lowering carbon footprint in factories. Manufacturers save energy while meeting strict environmental compliance standards. Hence, Honghui ovens combine productivity with eco-friendly operational efficiency.

Benefits of Using Honghui Technology Reflow Ovens

One major benefit is the balance between performance and affordability offered. Honghui ovens provide competitive features without the premium pricing overhead. This makes them attractive to small and medium-scale electronics producers. Cost efficiency enables more manufacturers to access advanced soldering technology. As a result, adoption rates continue increasing across global production facilities.

Reliability is another significant advantage of Honghui technology reflow soldering ovens. Consistent thermal performance translates to fewer defects during mass production. Reduced defects mean lower rework costs and improved overall yield. Manufacturers can meet deadlines with greater confidence and operational stability. Thus, Honghui ovens provide tangible business value beyond technical specifications.

Flexibility further strengthens the case for Honghui reflow soldering ovens. They support diverse product categories including LED lighting and automotive electronics. Adjustable profiles accommodate boards with complex geometries or sensitive materials. This versatility ensures suitability across different industries and manufacturing demands. Ultimately, Honghui technology ovens deliver efficiency, adaptability, and long-term return on investment.

User-Friendly Controls and Monitoring

Modern Honghui technology ovens include intuitive digital control panels for easy operation. Operators can store multiple soldering profiles for different manufacturing tasks. These controls simplify adjustments during production without interrupting workflow. User-friendly design minimizes training requirements for new factory staff.

Monitoring features allow real-time tracking of oven performance and profiles. Temperature data can be reviewed for quality assurance and consistency. Alerts notify operators of deviations, ensuring rapid corrective measures. Such capabilities strengthen reliability in demanding electronics manufacturing environments.

Applications in Modern Electronics Manufacturing

Honghui ovens are used in consumer electronics manufacturing on a large scale. Products like smartphones, tablets, and wearable devices require precise soldering. These ovens ensure solder joints meet durability and reliability standards. Even with small, complex boards, temperature control remains consistently accurate. Hence, manufacturers trust Honghui technology ovens to deliver production line dependability.

Automotive electronics represent another strong application for Honghui technology reflow ovens. Advanced driver systems, infotainment, and sensors require robust soldering processes. Honghui ovens provide reliable temperature profiles for sensitive automotive circuits. This ensures components endure extreme environments and long operational lifespans. The automotive industry benefits greatly from their durability and cost efficiency.

In LED lighting production, Honghui technology ovens support large board soldering tasks. They accommodate wide panels while maintaining even heating distribution. This results in strong solder joints across multiple LEDs simultaneously. Energy-efficient operation makes them practical for high-volume LED manufacturers. Therefore, their applications extend across lighting, displays, and other optoelectronic industries.

Compatibility with Lead-Free Standards

Honghui ovens fully support lead-free soldering processes in compliance with RoHS. They maintain peak temperatures required for unleaded solder without failures. Robust heating elements handle demanding cycles under lead-free conditions. This ensures consistent joints that meet international safety and quality regulations.

The design incorporates cooling systems for stable temperature transitions afterward. Proper cooling prevents micro-cracks or weak spots in solder joints. This reliability makes them suitable for global exports and certifications. Therefore, Honghui ovens are future-ready for evolving environmental standards.

- Multi-zone heating technology ensures accurate profiles and prevents soldering defects.

- Energy-efficient insulation lowers costs and improves environmental sustainability efforts.

- User-friendly controls allow simple adjustments and fast operator learning curves.

- Lead-free compatibility meets global regulations for RoHS and environmental compliance.

- Wide applications across consumer electronics, automotive, and LED manufacturing industries.

Faq’s

What is the main purpose of a reflow soldering oven?

It heats solder paste to form reliable electrical joints on PCBs. Controlled temperature ensures defect-free assembly in modern electronics manufacturing.

What is the main purpose of a reflow soldering oven?

Yes, it reaches high peak temperatures suitable for lead-free standards. Strong insulation ensures energy efficiency while maintaining required heat levels.

How many heating zones are typically found in Honghui ovens?

Most models feature multiple zones allowing precise thermal control. Independent settings help adapt profiles for different assembly requirements.

Are Honghui technology ovens suitable for small and medium-scale manufacturers?

Yes, their cost-effective design supports prototyping and mid-level production. Flexible configurations make them ideal for various industrial applications.

What benefits do Honghui ovens provide compared to traditional models?

They combine energy efficiency with stable temperature control performance. User-friendly interfaces simplify training and increase operational productivity.

Conclusion

Honghui Technology reflow soldering ovens provide reliable solutions for electronics manufacturing. Their multi-zone heating precision ensures consistent solder joints across all assemblies. Energy-efficient operation reduces costs while supporting environmental compliance requirements. User-friendly controls simplify operations and reduce training needs for staff. These features make Honghui ovens suitable for both small and large producers.

Lead-free compatibility strengthens their role in modern RoHS-compliant production environments. Robust heating elements handle demanding profiles without compromising product quality. Strong insulation improves safety while minimizing overall power consumption. Manufacturers benefit from reduced defects and improved yield through consistent results. Thus, Honghui ovens offer both technical reliability and financial efficiency together.

The applications extend across consumer electronics, automotive, and LED manufacturing industries. Flexibility ensures adaptability to various board sizes and production requirements. Global manufacturers recognize their value as cost-effective, dependable equipment choices. Investment in Honghui ovens supports long-term growth and manufacturing stability. Overall, these ovens balance performance, affordability, and sustainability in electronics production.

Read more latest Articles on Mobilestecy.com