Modern dentistry has evolved rapidly with the introduction of advanced digital tools. Among these innovations, CEREC technology stands out for transforming dental procedures. It allows dentists to design and create restorations within a single visit. This system eliminates traditional impressions, lab delays, and temporary restorations entirely. Patients benefit from faster treatment, improved accuracy, and greater overall comfort.

CEREC stands for Chairside Economical Restoration of Esthetic Ceramics in dentistry. It combines digital imaging, 3D modeling, and in-office milling technology seamlessly. Dental professionals use it to fabricate crowns, veneers, and onlays instantly. What once took weeks now takes just a few convenient hours. This innovation enhances efficiency while maintaining high-quality and natural-looking restorations.

As patient expectations rise, dental practices must adopt more efficient solutions. Digital Crown Fabrication empowers clinics to deliver superior service with reduced appointment times. Its precision and speed make it a game-changer in modern practices. By investing in CEREC, dentists stay ahead in a competitive market. It’s not just technology—it’s the future of personalized, same-day dental care.

Table of Contents

How CEREC Technology Works in a Dental Office

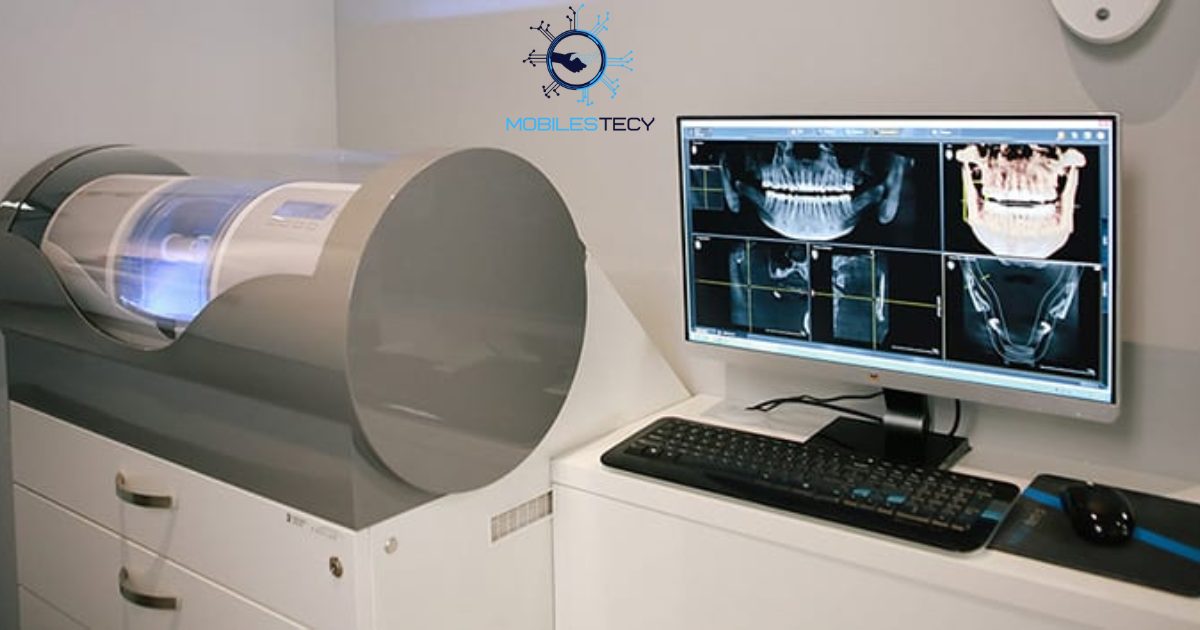

CEREC technology starts with a detailed digital scan of your mouth. The dentist uses an intraoral camera to capture 3D images instantly. These scans eliminate the need for messy, uncomfortable traditional impressions. The process is quick, clean, and accurate down to fine details. Patients experience greater comfort with no need for physical mold materials.

Once the digital image is captured, it enters a computer-aided design system. The dentist uses CAD software to design your custom restoration precisely. The software suggests optimal shapes and contours for a natural appearance. Adjustments can be made in real-time before sending to the mill. This digital workflow ensures a perfect fit tailored to your anatomy.

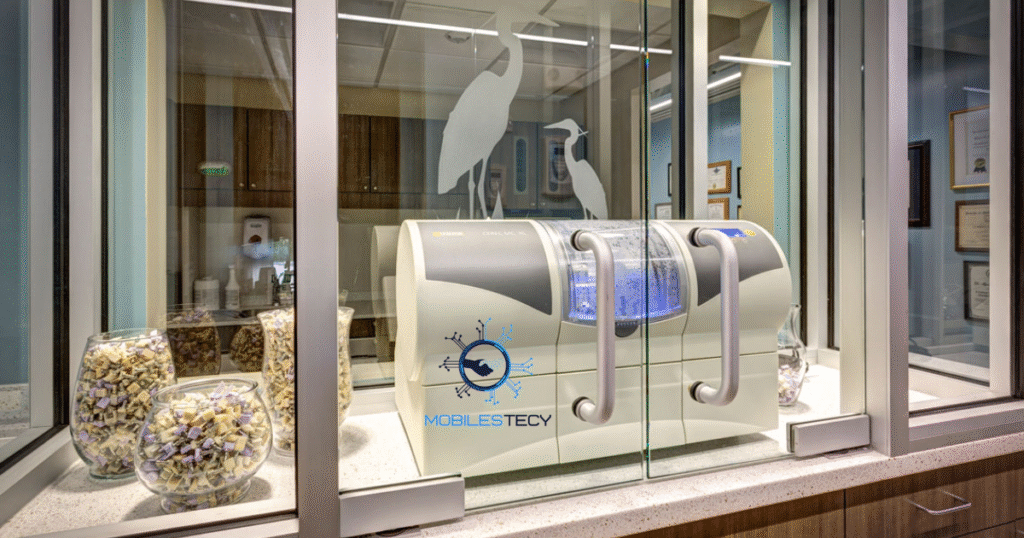

After the design is finalized, it’s sent to an in-office mill. The milling unit carves the restoration from a ceramic block efficiently. This process usually takes about 15 to 30 minutes total. Once finished, the restoration is polished and prepared for placement. The dentist bonds it to your tooth, completing the procedure same-day.

Benefits of Digital Crown Fabrication for Patients and Dental Practices

Patients love CEREC because it saves them valuable time and effort. No more multiple visits or wearing uncomfortable temporary restorations between sessions. Same-day service means fewer disruptions to your daily work or life. CEREC procedures are also more comfortable and less stressful overall. It’s a smoother, more convenient experience from start to finish.

For dentists, Digital Crown Fabrication increases efficiency and eliminates reliance on dental labs. Fewer appointments free up the schedule to treat more patients daily. Digital precision reduces remakes and adjustments, saving both time and money. Better accuracy leads to longer-lasting, higher-quality dental restorations every time. It improves patient satisfaction and enhances practice reputation and referrals.

The aesthetics of Digital Crown Fabrication restorations are another major selling point. Ceramic materials match the natural look and feel of real teeth. They are stain-resistant, biocompatible, and incredibly durable over many years. CEREC restorations blend seamlessly, making them nearly invisible when smiling. Patients leave with beautiful, functional teeth that restore full confidence again.

Patient Experience with Digital Crown Fabrication Restorations

Patients appreciate the speed and comfort of the CEREC process. Digital scans are faster, cleaner, and far more comfortable than molds. No temporary crowns are needed, avoiding extra appointments and potential issues. This technology creates a smooth, stress-free visit from start to finish.

Seeing the restoration created in-office builds patient trust and satisfaction. The process feels high-tech, modern, and personalized for their specific needs. Patients often express surprise at how quick the results are delivered. Same-day smiles leave a lasting impression that encourages word-of-mouth referrals.

Components and Equipment Used in Digital Crown Fabrication Technology

The first key component of Digital Crown Fabrication is the digital intraoral scanner. It captures a detailed 3D image of the mouth in minutes. Popular models include CEREC Omnicam and the newer Primescan systems. These scanners provide vivid, full-color visuals with incredible depth and accuracy. They are compact, user-friendly, and ideal for chairside scanning procedures.

Next comes the CAD software, where the restoration is digitally designed. It allows customization of shape, size, contour, and contact points. The software automatically generates suggestions based on tooth anatomy and bite. Dentists can refine the restoration for better aesthetics and function easily. This step ensures a precise and tailored restoration for every patient.

Finally, the design is sent to the in-office milling machine. This unit carves the crown or veneer from a ceramic block. Machines like the MC XL or Primemill work quickly and accurately. In 15 to 30 minutes, the final piece is produced efficiently. It’s then polished or glazed before being cemented into place.

Why Digital Crown Fabrication Represents the Future of Dentistry

CEREC technology aligns perfectly with growing demands for convenience and speed. In today’s world, patients want fast, reliable solutions without long delays. Same-day crowns help busy individuals maintain healthy smiles on tight schedules. It reduces anxiety by avoiding temporaries and long waits between appointments. Digital Crown Fabrication meets these needs while ensuring lasting results and beauty.

As digital dentistry continues to evolve, Digital Crown Fabrication leads the innovation wave. Integration with AI and cloud-based systems is improving design capabilities. Materials are advancing too, offering stronger, more aesthetic restoration options. The workflow keeps getting faster, more intuitive, and easier to implement. These improvements will only enhance patient care and clinical outcomes further.

Dental offices adopting CEREC stand out as modern, tech-forward practices. They attract more patients seeking efficient, comfortable, and quality treatments. Offering same-day restorations enhances reputation and trust in the community. It also boosts revenue by streamlining operations and reducing overhead costs. In many ways, Digital Crown Fabrication is setting new standards in dental excellence.

Training and Implementation for Dental Professionals

Dentists undergo specific training to fully master Digital Crown Fabrication technology tools. Courses cover scanning, design software, material selection, and milling techniques. Hands-on experience helps providers feel confident offering same-day restorations. Many manufacturers offer certification programs and continuing education options regularly.

Dental teams must also learn to support the new digital workflow. Assistants often help with scanning, design setup, and machine operation. With training, the entire team contributes to a more efficient practice. A smooth implementation improves productivity, morale, and overall patient satisfaction too.

- CEREC provides same-day crowns, eliminating the need for multiple visits.

- Digital scans replace messy impressions with clean, fast, and accurate imaging.

- In-office milling machines produce restorations in under thirty minutes.

- Digital Crown Fabrication restorations use durable, natural-looking ceramic materials for great aesthetics.

- Adopting Digital Crown Fabrication boosts efficiency and reduces dependence on external dental labs.

Faq’s

What is CEREC technology and how does it benefit patients?

CEREC creates dental restorations in one visit using digital imaging tools. It saves time, eliminates temporaries, and improves comfort and accuracy.

How long does a Digital Crown Fabrication crown appointment usually take?

Most Digital Crown Fabrication crown procedures are completed in about two hours total. Scanning, designing, milling, and placement all occur during the same visit.

Are Digital Crown Fabrication restorations as strong as traditional lab-made crowns?

Yes, Digital Crown Fabrication crowns use durable ceramic and match natural tooth strength. With proper care, they can last many years like traditional crowns.

Is the Digital Crown Fabrication scanning process comfortable for all patients?

Yes, digital scans are quick and avoid messy traditional impression materials. Most patients find the process smooth, clean, and very comfortable.

Can Digital Crown Fabrication be used for veneers, inlays, or onlays too?

Absolutely, Digital Crown Fabrication works well for crowns, veneers, inlays, and onlays. It provides custom restorations tailored precisely to each patient’s needs.

Conclusion

CEREC technology has redefined the way modern dentistry serves its patients. By combining speed, precision, and aesthetics, it enhances clinical care greatly. Patients benefit from quicker appointments and restorations that look and feel natural. Dentists gain efficiency, accuracy, and control over the entire treatment process. This innovation supports both quality outcomes and an improved patient experience overall.

Dental practices adopting Digital Crown Fabrication are staying ahead in a competitive field. Same-day services attract busy patients seeking convenient, reliable dental solutions fast. The ability to create restorations in-office reduces lab dependency significantly. With proper training, teams can fully integrate Digital Crown Fabrication into daily workflows. This investment in technology delivers long-term value for practice growth and success.

Looking ahead, CEREC will continue evolving with smarter tools and materials. Artificial intelligence, cloud integration, and advanced ceramics are shaping the future. Practices embracing digital dentistry will lead in both care and innovation. Digital Crown Fabrication isn’t just a tool—it’s a complete patient-focused solution today. It’s changing expectations, raising standards, and transforming modern dental care forever.

Read more latest Articles on Mobilestecy.com